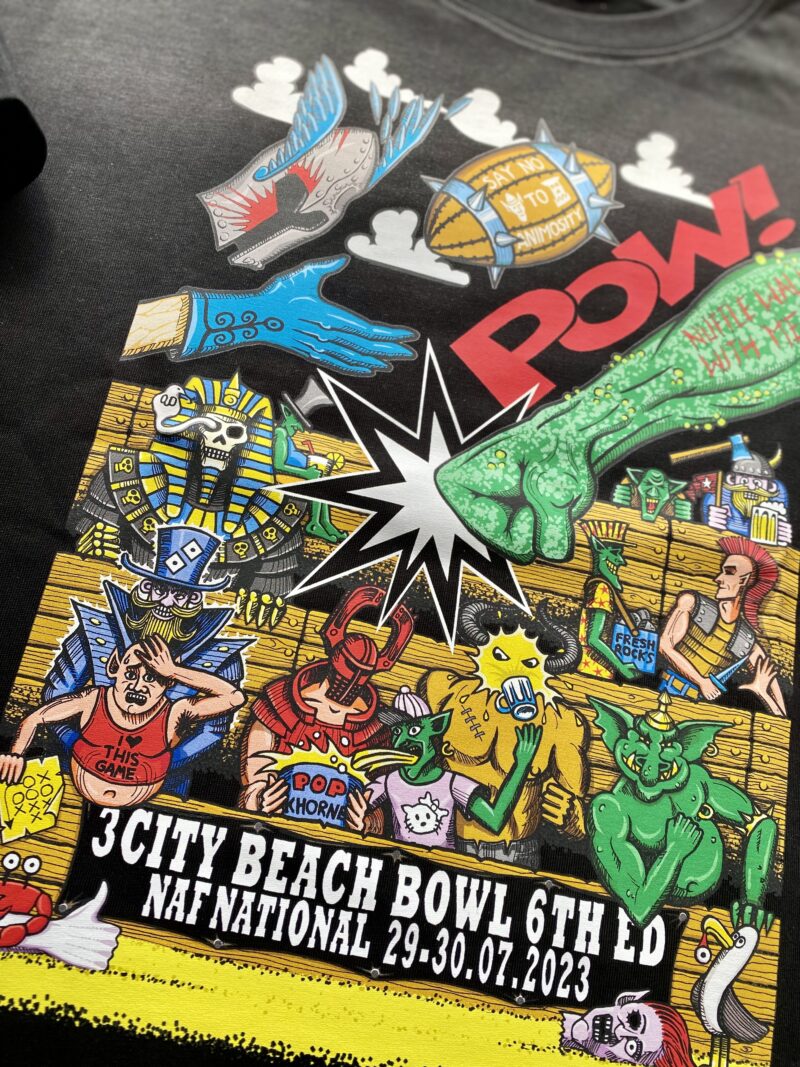

Screen printing is used commonly on textiles, such as t-shirts, caps, bags, sweatshirts, work wear etc. This method is best suited to cover large, flat surfaces. If done correctly, screen printed designs are resistant to wear and laundering. They are also quite cheap when ordered in bulk. Screen printing involves pushing paint through exposed moulds (sieves) using a squeegee (manual or automatic). The sieves are in turn installed in a screen printing carousel.

Full colour gamut

The best thing about screen printing is that you can print in any colour. You can mix colours after all, and a special piece of software will measure precisely the amount of pigment needed. After preparing files for exposure in the right way, tonal transitions (gradients) are also possible, as is a full colour print. There are various kinds of screen printing paint, however plastisols are most commonly used. Among others, are for instance water or discharge paints. Each type of paint requires different preparation of the materials, on which a design is to be applied. The printing process can also be different. A rarely used, but interesting alternative, is the special effect paint. It allows for the use of various special effects, such as:

Very high resistance to laundering

Done right, the printed design will not peel away during laundering! What to we mean by doing it right? Consider each stage of the process: exposure, paint quality, printing, drying. If each stage is done according to the rules of the craft, the printed design will be durable and no washing machine will do it harm. It will survive the material, on which it is

printed.

Screen printing likes larger numbers

You’re probably familiar with the rule that the more you order, the less you pay. This is exactly the case with screen printing. Keep in mind that there are some fixed costs to consider when using this method, which are dependent on volume. This is mainly about print preparation, i.e. preparing plates and exposing them properly to create moulds. Each additional colour means one more sieve to expose.

EXAMPLE: It costs 12 EUR to prepare one sieve. This is spread throughout the order. 1000 pieces using one colour = 0,01 EUR per piece; 100 pieces = 0,12 EUR per piece; and 20 pieces = 0,6 EUR per piece. And that’s just the cost of preparing sieves – you need to add the cost of printing as well.

The example above shows just how important is thinking ahead. The higher the number of t-shirts and sweatshirts, the lower the price per piece.

Printing on coloured and dark fabrics

It’s worth noting that when printing on t-shirts, sweatshirts and other coloured or dark items of clothing, a white-coloured base is applied under the actual print to achieve the right colour. Not doing this would result in the colour of the fabric being visible through the design. Therefore, when printing colourful designs on dark clothes you have to consider an additional sieve. In some cases, you may be able to use a trick, which will allow you to save on printing the base separately. What’s the trick, you ask? If your design already features the white colour, you can use it as a base at the same time!

Thus, the final cost of printing is dependent on two factors:

- print run, or how many pieces to order

- number of colours

Our offer includes screen printing starting from just 20 pieces. Usually, printing firms only consider screen printing with orders of 50 or even 100 pieces. Our screen printing carousel allows for printing of up to 10 colours in one run. If you don’t need larger volumes, you might want to try thermal transfer or digital print.

IMPORTANT: Remember, there’s no such thing as the “best possible printingmethod.” Each and every method has its pros and cons. Operator’s skills are an important (if not all-important) factor as well, as are the materials and equipment used. Other “non-technical” aspects are important as well, such as individual taste and expectations of the client regarding the end result. It is the job of a professional company to suggest the most effective solution, tailored to your needs.

FUN FACT: The roots of screen printing can actually be traced back to ancient Japan. To learn more about it, visit our blog.

I ordered last minute as usual, but the service was quick and professional. It was a big surprise, that although the volume was low, Printexpress.pl has printed it in a screen method with a very good price as well.

Wojciech Pietrzak, Bullsheep.pl