Pigment Migration – How to Prevent It

Dye migration is a problem that can spoil our day, especially when we discover that the print on a polyester T-shirt or an expensive softshell jacket is starting to take on color. Sometimes this effect is not immediately apparent when the film is indented, but may appear only after a few hours or days.

Why does this happen? Migration of dyes by dispersion dyeing.

In the case of polyester fabrics, dye migration is due to the way the fabrics are dyed. Dyeing of polyester fabrics is possible not only by sublimation, but also by dispersion. During the process of dyeing fabrics, the fibers open up when exposed to heat, the pigments go into a gaseous state at temperatures above 190°C, and then disperse or dissolve. Once cooled, most pigments become “trapped” in the polyester fibers and do not migrate. However, if you now heat the textile piece above 130°C, the polyester fibers open up again, and the pigments begin to migrate to the surface of the fibers, leading to the dyeing of the print.

To avoid pigment migration in the case of polyester fabrics, a lower transfer temperature can be used. Then the polyester fibers remain closed, and the small amount of pigments on the outside of the fibers does not cause problems. Using a film with a dye blocker can help prevent this small migration.

The problem with softshell jackets

This topic is more complicated. First, these types of jackets are composed of microfibers, which are difficult to clean of excess pigments. Second, they contain elastic fibers, such as Lycra or Elastane, which are more prone to dye migration, even at lower temperatures.

In the case of Softshell jackets, the excess pigment remaining on the fibers can be so large that the blocking film itself is unable to prevent migration. This is due to the amount of pigments and their distribution on the surface of the material. To prevent this, you need to choose a suitable film that requires a lower temperature plus additionally contains a blocker that will prevent migration.

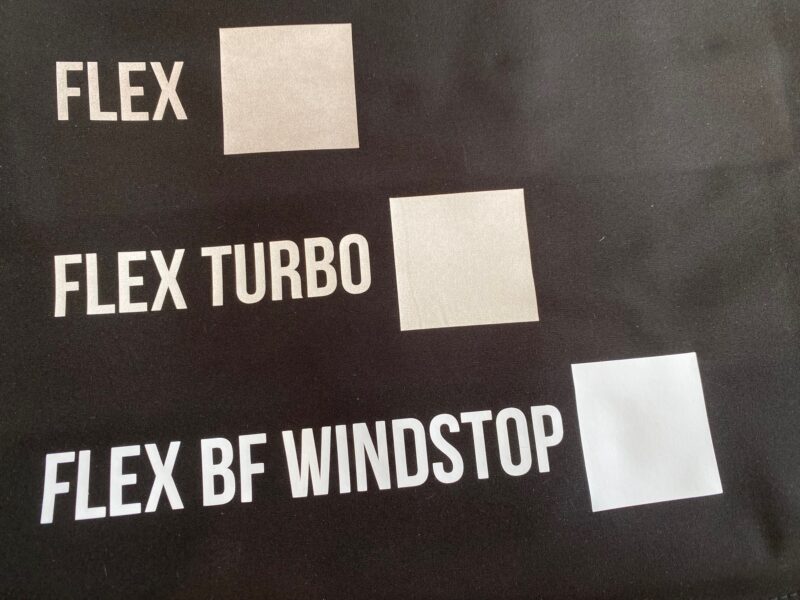

An example of such an innovative film that prevents dye migration is Flex BF WINDSTOP. It is a polyurethane film coated with a heat-activated adhesive that is ideal for decorating waterproof jackets, caps, boots and other synthetic fibers with graphics. Its built-in blocker prevents ink migration, allowing you to print bright colors on dark fabrics.

It is also worth remembering that film is not the only solution. If you want a lasting effect and minimize the risk of dye migration, you can dispense with transfer and use other methods, such as embroidery.

It’s worth understanding the problem of dye migration and choosing the right solutions to achieve durable and impressive prints on textiles.