Ah, that fussy cotton….

There are probably no people who don’t like original and distinctive clothing. Nowadays There are plenty of different printing techniques that can be tailored to a particular design, still the biggest difficulty is multicolor printing on cotton. If you only need one or a few pieces, screen printing will prove to be a technique that is too expensive, while thermal transfer will make it impossible to produce prints with tonal transitions (so-called gradients) and with a structure that is too complex, consisting of many small elements.

The ideal solution would seem to be sublimation, this one, unfortunately, only works on plastics, and not everyone likes to wear T-shirts with a touch of polyester, even though today’s products of this type are already really similar in feel to cotton and often just as pleasant to wear.

There is, of course, DTG or direct computer printing. You can print from one piece, on cotton and in full color, while there is still a technique that will provide even greater durability and even better color reproduction than computer printing. Get to know subli-flock!

Cotton Grail?

Ta teThis technique is like a combination of thermal transfer and sublimation. The printing process in this case consists of 4 steps.

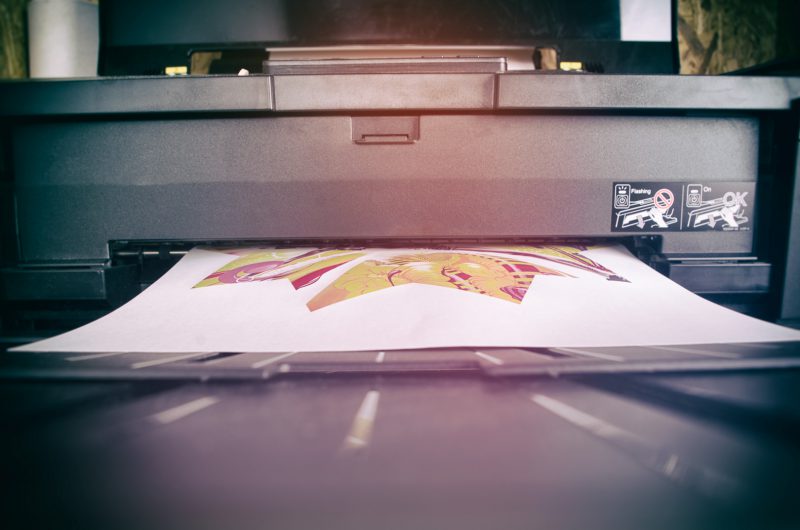

The first is to prepare and print a design with a sublimation printer, which will then be placed on a T-shirt, bag or other cotton product. An interesting fact is that the sublimation ink on the transfer paper can have completely different colors than those that will eventually fix on the substrate. But wait, wait… after all, I just wrote that sublimation will not work with cotton….

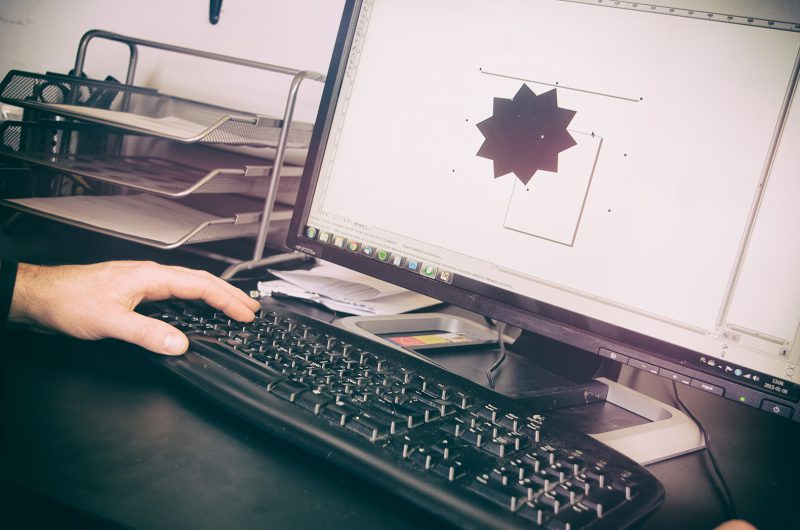

…Therefore, the next step is to prepare a suitable substrate that will react with the sublimation ink. For this purpose, a thin plastic film is used, on one side adapted for sublimation printing, and on the other side to be applied to cotton using a thermopress. Now do you see why I stated that it is a combination of sublimation and thermal transfer? The appropriate shape of the film (so that it coincides as closely as possible with the planned print) is cut with a cutting plotter. The two parts of the print need to be very precisely aligned otherwise you may find that the print will be cut in an odd way somewhere.

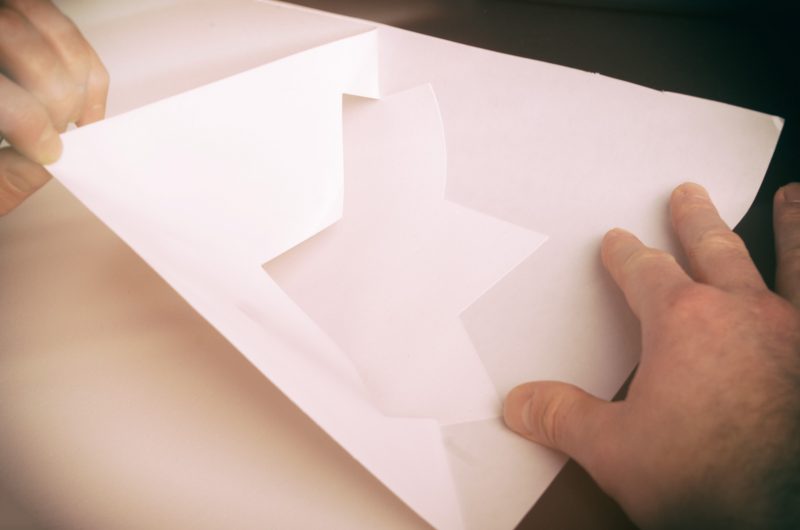

If everything is already elegantly fitted, we move to the third phase, in which we need to transfer the print from the transfer paper to the sublimation substrate using a thermopress. This is the moment when we will know if everything has gone as expected and the print has sublimated in its entirety. If it has, we carefully peel off the subli-flock film with the finished print and….

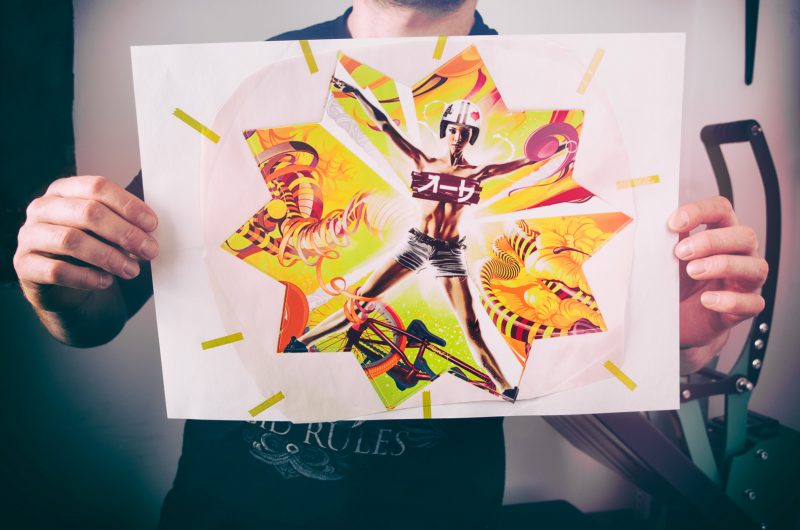

…we move to the last, fourth stage. This one is practically no different from the traditional thermal transfer. We have to place a T-shirt or other printed gadget in the press, adjust the sublimation, set the right temperature and time and enjoy the final product with a crystal clear print.

Cotton counterattacks

Of course, cotton is a tough opponent and it is not the case that this printing technique will satisfy everyone. First of all, the print is perceptible, because it is applied on subli-flock film, which, unfortunately, is slightly thicker than traditional flex. In addition, it is not possible to print small and complex shapes.

Summa Summarum

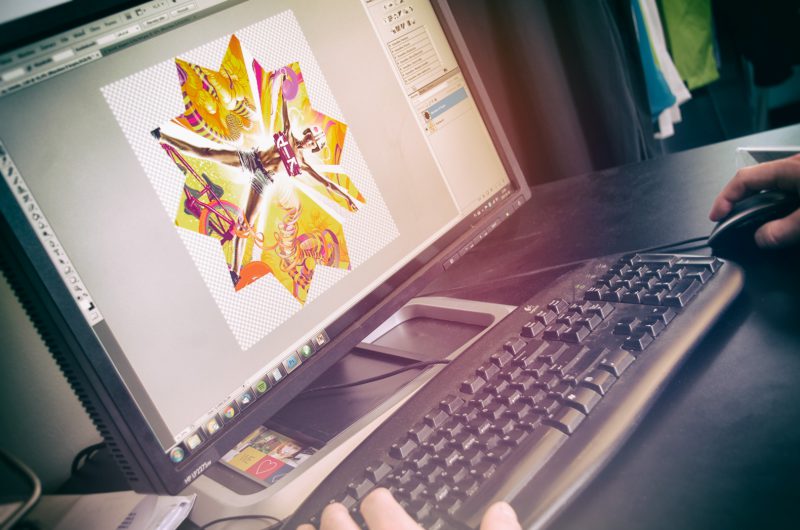

Subli-flock is a great technique if we want a durable print with our favorite motif, or simply one that incorporates multiple colors and gradients. We don’t have to worry about the colors washing out, a print made this way is virtually indestructible. Like Superman. Well, and maybe this is the idea for your first subli-flock print? :)