DTF printing – advantages and disadvantages

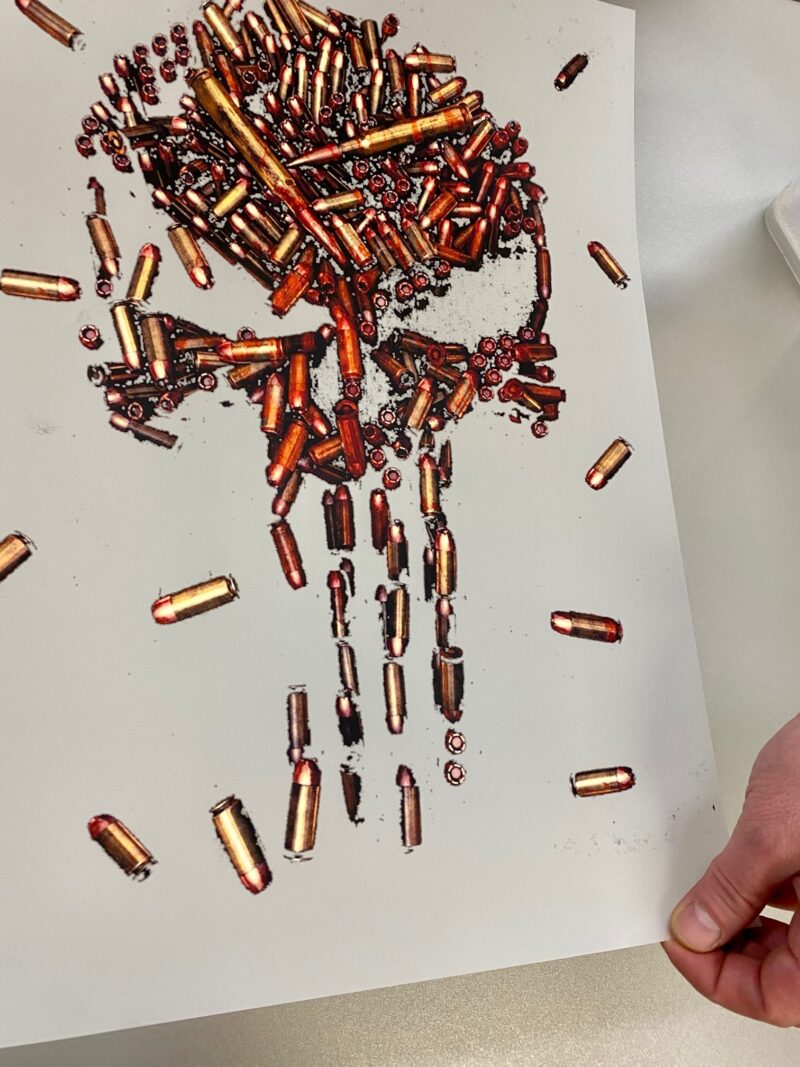

Printed using the DTF (Direct to Film) digital method, it has vivid colors and clear graphic elements. In appearance, it resembles screen printing. T-shirts printed with DTF are pleasant to the touch, and the ink is durable on a variety of materials.

If we are to compare with another digital method, namely DTG, one disadvantage of DTG printing is that it requires a pre-processing step. With DTF printing, this is not necessary. In order to apply a preprinted design to a garment, it only needs to be printed on a printer adapted to this method, in our case a Brother GTX PRO printer, and pressed into the garment using a heat press. No pre-processing is required. Below we will outline some of the advantages and disadvantages of DTF printing.

What is the printing process like?

For DTF printing, you need to use a special transfer film. The printer prints the image, directly on it. After the printer prints the transfer film, a special adhesive powder is applied. The film is then transferred to an oven so that the glue binds to the ink. After this process, the print is transferred from the film, using a heat press, into a T-shirt or other garment. Everything takes very little time and is easy to apply.

Additional advantages of DTF

Small lettering and complex lines of graphics can be reproduced well using DTF technology. The use of direct film printing also eliminates colorfastness problems. Once the ink dries, the color will never fade or change. Printing on film using a DTF printer produces sharper images than conventional techniques.

Advantages and disadvantages of DTF printing

Benefits of DTF printers include:

- Exceptional print quality:

DTF printing on fabric produces an amazing high-resolution effect with saturated colors. It is ideal for graphics that have tonal transitions and multiple colors. As well as when printing photos on clothing. - Versatility:

DTF printing is quite versatile in terms of product as well as material. Cotton, light polyester, denim, hats, promotional bags, sweatshirts, softshell jackets. - Personalization:

Because DTF printers can print patterns, photos and text onto fabrics in a variety of colors, they provide a high degree of personalization. - T-shirts:

Any color cotton T-shirts are suitable for DTF printing. There are no color restrictions.

Some possible drawbacks of DTF printing:

- Printer cost:

The high initial cost for a DTF printer (in our case it is a Brother GTX PRO printer) has a significant impact on the price of DTF printing itself - Ink price:

The high ink consumption of DTF printers can also be a significant factor in the high cost of printing. However, it must be very strongly emphasized here that such a high end when it comes to the printer itself as well as the inks for it, give a unique and exceptional printing effect on T-shirts. Working on original, branded inks gives us a guarantee of the durability of the print. - Printing time:

The printer prints at a good rate, but with large quantities this time proves to be significant when calculating the turnaround time of the entire order.

Is DTF printing of good quality?

DTF printing is widely regarded as a high standard for printing on textiles. Fabrics printed using DTF behave well in the wash. The end result on garments is very pleasant to the touch. This opens up many possibilities for designing and making unique prints on different fabrics.

Also note that the print quality on a DTF printer can vary depending on the machine and ink. Better quality prints will be made with DTF printers and higher-end inks, which ultimately affects printing costs. Nonetheless, DTF printing is widely regarded as a very good quality multicolor printing on fabric.